SURE32 grinding system - based on a CNC Sinumerik 840D

SURE32 is a highly efficient control system of roll grinding machines - developed from Vosswinkel based on decades of experience. The system originated and further grows to do justice to the demands of the practise:

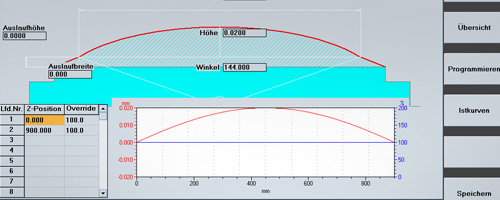

- grinding of rolls with any highly accurate profiles.

- calculation any ball forms up to and including CVC - curves

- pre-, finish , and precision machining of work and backup rolls

- grinding of cylindrical and hollow and spherical cambered rollers

- grinding tapered roll neck

- grinding of rolls with chocks

- measurement of the ground roll in the grinder

- surveying online, during grinding or offline

(that is, after completion of the grinding process) - logging of the entire grinding process

- numerical and graphical documentation of the finished ground roll barrel

- easily create the grinding programs via universal cycles

- various functions such as grinding surface grinding , taper grinding , plunge grinding , screw grinding, cone grinding

- creating and Enabling bed path corrections

- align the roller in the machine using the probes

- grinding wheel Management

- curve programming and management

- linear, circular and diameter measurement

- automatic or manual putting on of the probe to the roller

- measure with target- curve comparison and representation of a tolerance curve

- calculate and grinding of the correction curves from target - actual - Comparison

- consideration of factors such as machine bed errors , errors due to Temperature and roll weight , as well as errors of the infeed by machine geometry and possible misalignment of the roll

- create the machine documentation

- user-friendly screens for service, setting and commissioning

- on-site commissioning and operator training

- worldwide service of the control system